Daily maintenance:

* print head status diagram before printing job and before shutting down every day to check and ensure that the status of the print head is normal

If the printing is not normal, click clean and then click print head- head status to print head test picture

* Regularly use cleaning liquid and cotton swabs to clean the Cap, wiper, and keep cap and wiper clean

* Before printing a job every day, turn on the ink stirring button, stir the white ink, and check whether the ink is sufficient

* Check the waste ink bottle regularly to ensure that the waste ink does not overflow

* Check water cooling tank regularly, keep the water tank water at about 80%

* Check encoder regularly to ensure that the optical decoder is dry and clean. If it is dirty, wipe it gently with alcohol

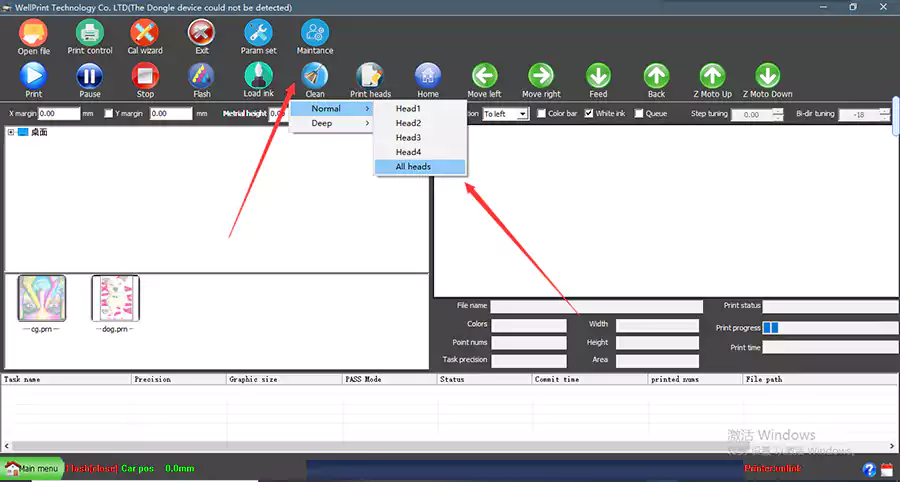

How to do print head clean by software

Click clean and all heads

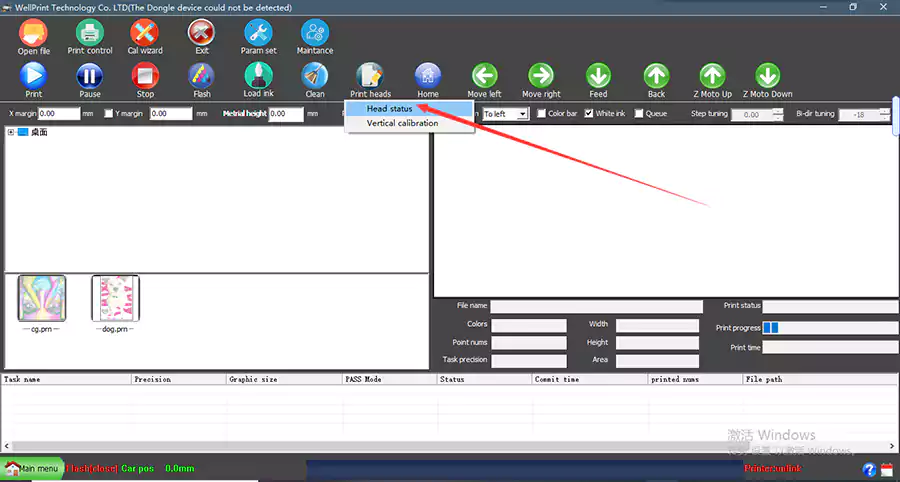

How to print head status test picture

Click print head --- head status to print test picture on glass or transparent acrylic to check cmyk, white and varnish color inks ok or not(before printing need to check print thickness, glass and transparent acrylic cant use height sensor to check printing thickness, need to move out print head onto glass to check printing thickness )

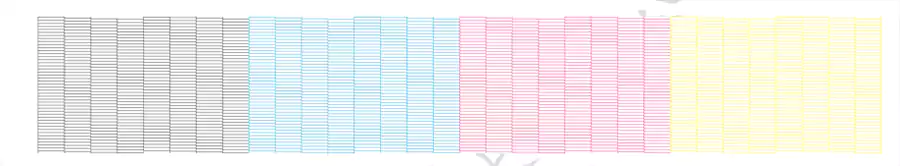

This is the right and suitable head status picture, If the test picture is poor, please click clean- all heads and print head status again, till test picture ok, if always still very bad after repeated several times, then please click load ink(3-5 seconds)

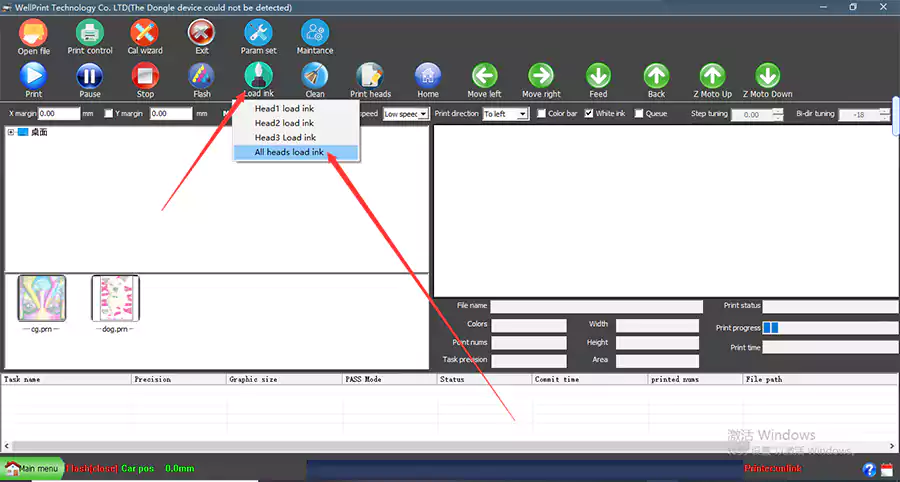

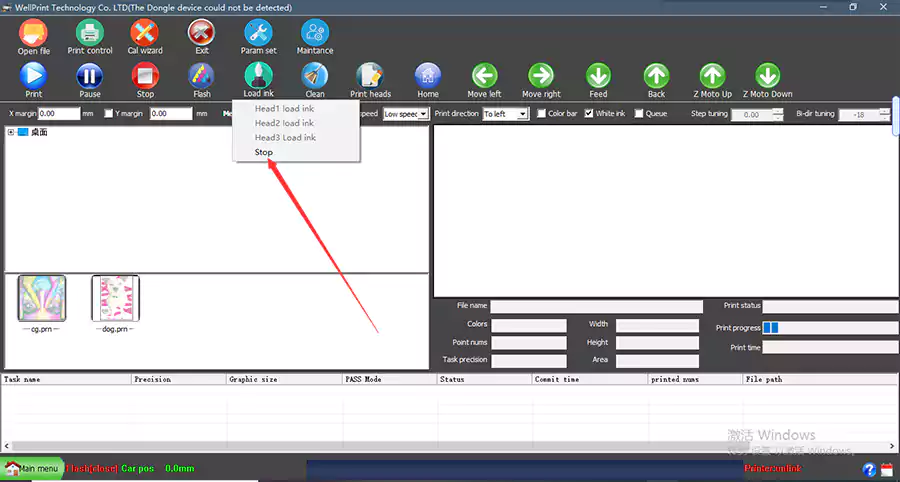

How to load inks by software

click load inks, choose all head or 1,2,3 heads, load inks only 3-5 seconds, than click load inks-stop

Note:Head 1 is white, head 2 is color, head 3 is varnish

3-5 seconds later, click stop

Then click clean, and then print the head status.

If the ink still does not come out, then we need to suck the damper with a syringe.

How to suck dampers by syringe: (please don’t with a needle)

Post time: Apr-05-2022